Keep Your Pond Perfect: Essential Diaphragm Pump Care Made Easy

Protect your diaphragm pump’s lifespan and maintain peak performance with proper maintenance – it’s simpler than you might think. Regular care prevents costly breakdowns, ensures consistent water flow, and extends your pump’s operational life by years. Whether you’re maintaining a pond pump or industrial equipment, following a structured maintenance routine is crucial. This guide walks you through essential diaphragm pump care, from basic cleaning procedures to preventive checks, helping you avoid common issues and keep your system running smoothly. By spending just 30 minutes each month on maintenance, you’ll save hours of troubleshooting and hundreds in replacement costs down the line. Let’s dive into the practical steps that will keep your diaphragm pump working efficiently for years to come.

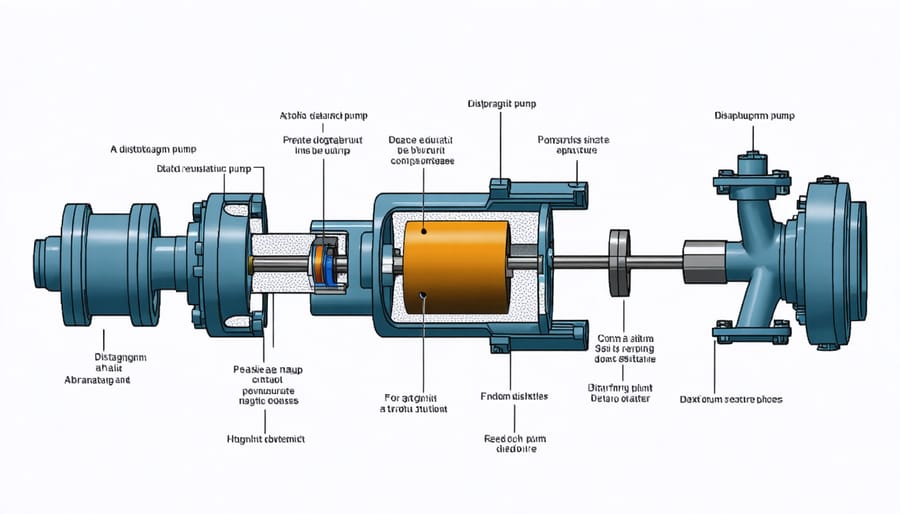

Understanding Your Diaphragm Pump

Key Components

A diaphragm pump consists of several crucial parts that need regular inspection and maintenance. The heart of the system is the flexible diaphragm membrane, which creates the pumping action and requires checking for tears or wear. The inlet and outlet valves control water flow and should be kept clean and free from debris to prevent blockages.

The pump housing protects internal components and needs inspection for cracks or damage. Check the motor and electrical connections regularly, ensuring they’re dry and corrosion-free. The shaft seals prevent water from entering the motor housing and should be examined for signs of leakage.

Other essential components include the pressure switch, which controls pump activation, and the pressure tank that helps maintain consistent water flow. The strainer or filter screen at the inlet prevents debris from entering the pump and needs frequent cleaning.

Don’t forget about the mounting hardware and vibration dampeners – these keep your pump stable and quiet. Regular attention to these components will extend your pump’s life and maintain optimal performance.

Regular Maintenance Schedule

Monthly Checks

Regular monthly checks are crucial for keeping your diaphragm pump running smoothly. Start by gathering your essential maintenance tools and performing a thorough visual inspection. Look for any cracks, wear, or damage to the pump housing and connections. Clean the pump’s exterior using a soft brush to remove any buildup of algae or debris.

Check all connection points and hoses for signs of leakage or wear. Ensure the inlet strainer is clear of debris and clean it if necessary. Listen to your pump while it’s running – any unusual sounds could indicate problems that need attention. Pay special attention to the diaphragm’s movement; it should operate smoothly without any catching or irregular motions.

Inspect the electrical cord for any damage or wear, particularly near connection points. Test the pump’s pressure output to ensure it’s performing at optimal levels. Finally, check and tighten any loose mounting bolts or screws, as vibration can cause them to loosen over time. Making these simple checks part of your monthly routine will help prevent bigger problems down the line.

Seasonal Tasks

As seasons change, your diaphragm pump needs different types of care to keep running smoothly. In spring, focus on clearing any debris that accumulated during winter and check the diaphragm for cracks that might have developed during freezing temperatures. Give the pump housing a thorough cleaning and inspect all connections.

Summer maintenance is primarily about preventing overheating. Keep the pump area well-ventilated and clear of plant growth that might restrict airflow. Check the pump more frequently during hot spells, as higher temperatures can strain the system.

Fall preparation is crucial for winter survival. Clean out any fallen leaves around the pump and consider adding insulation if you plan to run it through winter. If you’re winterizing the system, drain all water, disconnect the pump, and store it in a dry, frost-free location.

For year-round operation, install a protective housing or cover to shield against extreme weather. Remember that freezing temperatures can damage the diaphragm material, so extra precautions during winter are essential. Consider using a heating cable if you need to maintain pump operation in freezing conditions.

Common Problems and Solutions

Loss of Pressure

If your diaphragm pump isn’t delivering the expected pressure, start by checking the inlet strainer for debris or clogs. A blocked strainer is often the simplest cause of pressure loss. Next, inspect the diaphragm itself for tears or wear – even small holes can significantly reduce pumping efficiency. Listen for unusual sounds during operation, as these might indicate air leaks in the suction line.

Make sure all connections are tight and properly sealed. Loose fittings are common culprits for pressure loss. Check the pump’s inlet and outlet valves for proper operation, as stuck or damaged valves won’t allow proper flow. If these basic checks don’t solve the issue, examine the pump’s pressure relief valve, which might need adjustment or replacement.

Don’t forget to verify that your pump size matches your system’s requirements. An undersized pump will always struggle to maintain proper pressure.

Unusual Noises

A well-maintained diaphragm pump should operate with a steady, rhythmic sound. If you notice any knocking, grinding, or rattling noises, this usually indicates a problem that needs attention. A loud clicking sound might mean the diaphragm is worn or damaged, while a grinding noise often points to debris caught in the pump chamber. Squealing or whining typically suggests bearing issues or lack of lubrication.

Listen for unusual vibrations or changes in the pump’s normal operating sound. If the pump suddenly becomes louder or develops an irregular rhythm, shut it off immediately to prevent potential damage. Sometimes, strange noises can be fixed by simply tightening loose mounting bolts or adjusting the pump’s position. However, if unusual sounds persist after basic adjustments, it’s best to inspect the internal components or consult a professional.

Remember that some pumps naturally run louder than others, so familiarize yourself with your pump’s normal operating sound as a baseline for identifying problems.

Winterization and Storage

When temperatures start dropping, proper winterization becomes crucial for your diaphragm pump’s longevity. As part of your overall winter pond maintenance, you’ll want to protect your pump from freezing conditions that could cause serious damage.

Start by disconnecting the pump and draining all water from the system. Remove the pump from your pond and clean it thoroughly, paying special attention to the diaphragm and valve assemblies. Any leftover water could freeze and crack these components.

Store your pump in a dry, frost-free location like a garage or basement. Place it in a sealed container to keep dust and debris away. If possible, store it with the ports facing downward to ensure complete drainage. For added protection, you can wrap the pump in a clean cloth or bubble wrap.

Before storage, inspect all components for wear and tear – this is the perfect time to identify parts that might need replacement come spring. Make a note of any maintenance needs for easy reference when you restart the system.

Regular maintenance of your diaphragm pump is key to ensuring its longevity and reliable performance. By following a consistent cleaning schedule, checking seals monthly, and performing seasonal inspections, you’ll prevent costly repairs and extend your pump’s life. Remember, a well-maintained pump not only runs more efficiently but also uses less energy and provides better water flow for your pond or water feature. Make maintenance a habit, and your pump will serve you faithfully for years to come.